Production process

At FA Nutrition, we ensure superior quality in every supplement by following a meticulous production process. Our facility in Rusocin meets stringent standards, including GMP, HACCP, GHP, IFS, and Halal certifications. We also hold FDA certification, underscoring our dedication to safety and excellence in manufacturing.

Quality, from the beginning to the end of the process

The production of dietary supplements is a complex process involving many steps. Fitness Authority® is committed to ensuring consistent, superior quality throughout the manufacturing process.We set the standards

We have tailored our production to meet customer expectations and the standards of even the most demanding markets. The plant meets the highest standards in the areas of production process safety (GMP), quality assurance (HACCP), hygiene (GHP), food safety (IFS) and Halal. In addition, we are FDA-certified by the U.S. Food and Drug Administration, confirming that our products are safe, meet high quality requirements and have no negative health effects.Such a high standard has been achieved thanks to the division into safety zones and cleanliness classes, overpressure and the use of materials such as acid-resistant steel used in the making of walls and ceilings, multi-layer epoxy-polyurethane flooring, antibacterial mats between zones and many other solutions significantly exceeding the accepted standards in the supplement industry.

To maintain constant and optimal conditions in the production process, the plant has been fitted with a state-of-the-art ventilation and air conditioning system. Thanks to this solution, regardless of changing weather conditions, we are able to ensure consistent, highest quality and repeatability of our products.

Verification of raw materials

Before a batch of a given raw material is purchased, a sample of it is sent to the technology department along with the required quality documentation from the supplier, including certificates of analysis, other certificates and declarations. In order for the purchase to be completed, the sample must receive a positive qualitative and technological assessment.Raw materials are also inspected upon acceptance of delivery. At this stage, the quality assurance department takes reference samples from each batch. In the company's physical and chemical laboratory, quality tests are carried out to determine compliance with specifications and comparative evaluation with previously sent samples. Only those raw materials that received a passing grade in the tests are qualified for the next stage of production.

Quality control at each stage of production

Fitness Authority® employees undergo thorough training in order to consciously and effectively ensure the quality of the manufactured product, at every stage of its creation. Any deviation from the standards is immediately reported to the quality service, in order to implement adequate corrective actions.Thanks to the use of a precise ingredient weighing system, we are guaranteed that the right raw materials in strictly defined proportions go into the product. After all the ingredients are mixed, the mixture is subjected to a detailed quality assessment. Before hydration, the uniformity of the structure is checked – whether it is free of clumps, impurities and foreign bodies.

It is then subjected to quality testing in accordance with the scope of testing and inspection established for the product type. After hydration, it is subjected to sensory evaluation, during which its submersibility, solubility, odor and taste are verified.

We qualify for the next stage of production only those mixtures that receive a positive control evaluation.

We qualify for the next stage of production only those mixtures that receive a positive control evaluation.

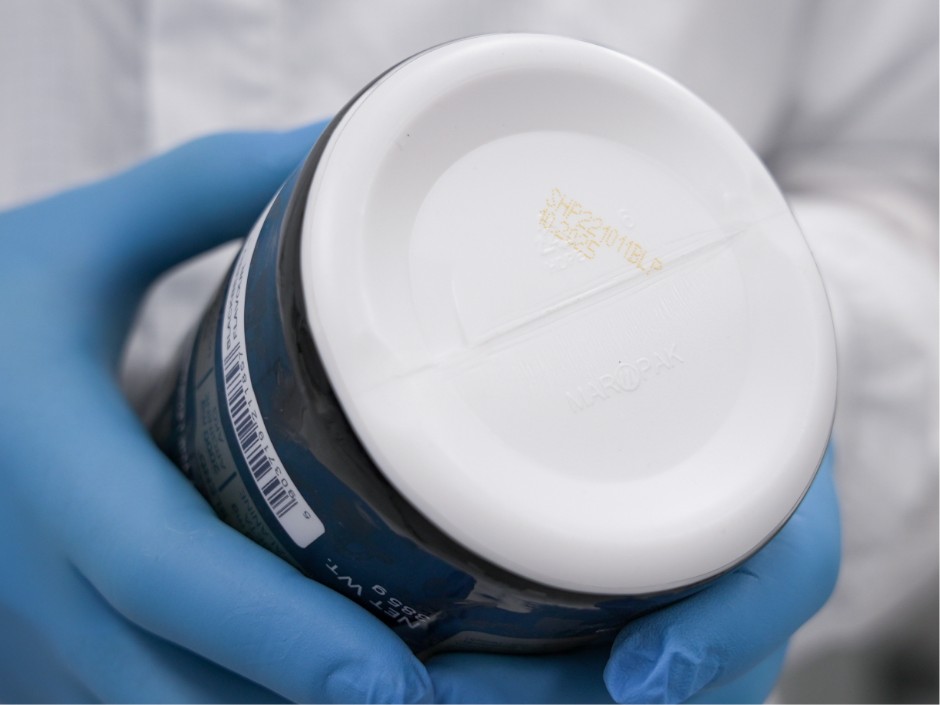

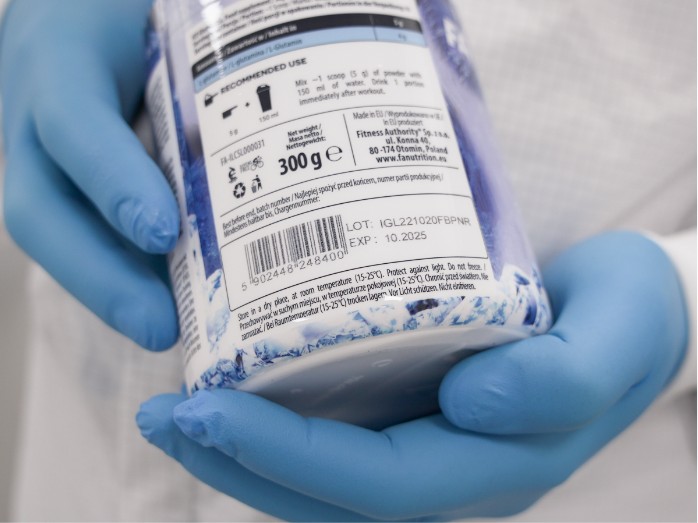

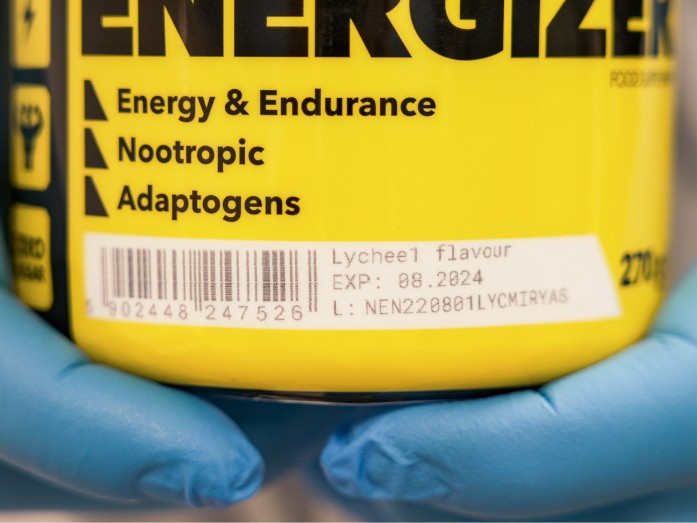

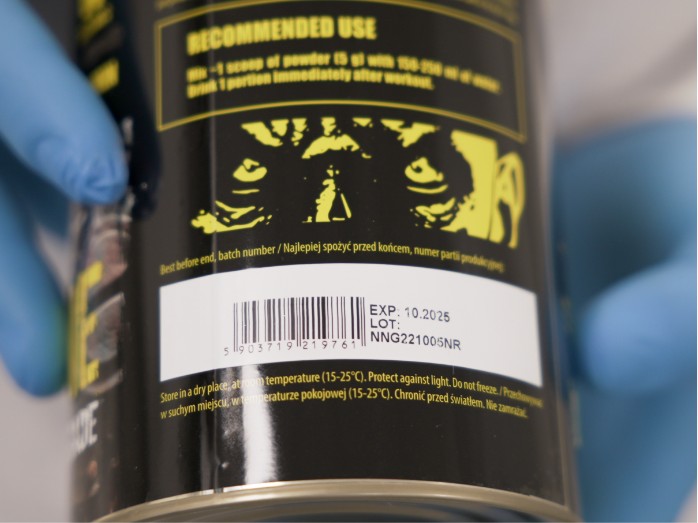

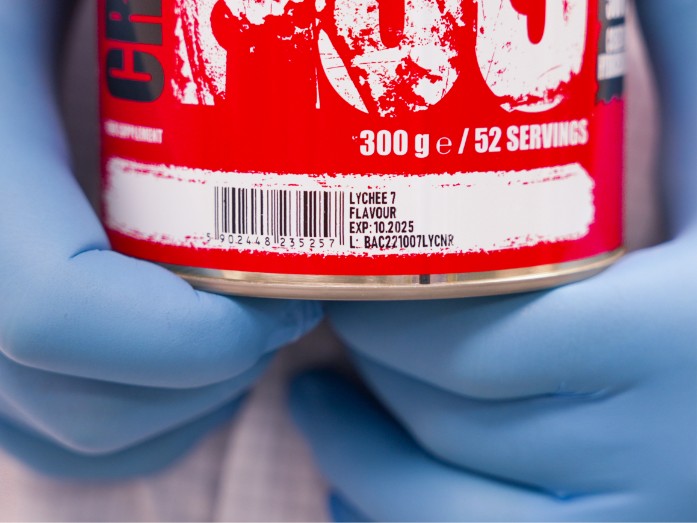

A number of 100% inspection points have been planned for the packaging process, with automatic rejection of products that do not meet the established acceptance criterion (packaged products control, metal detector, presence of induction insert, seal quality, and coding of unit and bulk packaging).

Before leaving the production plant, pallets of finished products are secured and marked with a logistics label. Thus prepared, they go to the Fitness Authority® distribution center in Otomin, from where deliveries are made directly to several hundred customers in more than 90 countries around the world.

Shots production

To ensure the highest standards of safety, quality and hygiene, an automatic CIP (Cleaning In Place) process takes place each time before and after the manufacturing process of Fitness Authority® shots. The station has 3 tanks - for alkaline cleaning, acid cleaning and rinsing.According to the formula of a particular product, all ingredients are precisely weighed and mixed. The base is then subjected to filtration and pasteurisation processes. This ensures that the liquid has the right clarity, is safe and remains fit for consumption for an extended time period. Simultaneously, the packaging is prepared.

The dietary supplements are bottled on the KHS InnoPET BloFill bottling machine, which allows as many as 80 containers to be filled simultaneously. The filled bottles are sealed on a capper coupled to a bottling machine and then go to an inspector where they are verified in terms of: capacity, cap and bottle colour, and whether the cap and seal have been properly screwed on.

Obligatory during and after production, the samples taken are subjected to physicochemical, microbiological and sensory analysis. Among other things, the following are inspected: product weight, volume, brix, ph, temperature, acidity, saturation of the product with carbon dioxide or nitrogen, osmotic pressure and, in addition, microbiological tests. Only shots that receive a positive result from the tests conducted are qualified for sale.

The filled bottles undergo shrink sleeve application. The use of this type of label allows it to match it to the distinctive features of the packaging. Thanks to hot steam shrinking, we are guaranteed a high level of precision and an even label placement, which results in a more durable and aesthetically pleasing product. After leaving the steam tunnel, each shot goes under the print head, which marks the caps with the batch number and date. The finished products are packed in cartons and heat-sealed. They are then stacked on a pallet, protected with foil and labelled. If you want to learn about the entire production process of our shots watch the video.

Product labeling options

Our state-of-the-art production line makes it possible to print information on self-adhesive and heat-shrinkable labels (sleeves) or directly on unit packaging. The use of dedicated color ink allows us to print on black containers as well. Thanks to these solutions, we can be sure that products leaving the packaging line are labeled in an aesthetically pleasing, legible and durable manner, and fully in accordance with the individual preferences of each customer.

Productiony efficiency

The production plant was established and is constantly being developed in response to growing customer demand, determined by the company's dynamic expansion into new foreign markets. By using the latest technology and automating and robotizing processes, we ensure impressive production efficiency for such a compact plant. With the implementation of three-shift production, we are able to produce nearly 40,000 pieces of products per day, which amounts to more than 9 million pieces per year.